Condor Huila San Agustin

Coffee farming in this remote region of South of Huila is different from other regions. More than farming it is an art; which has been passed on through generations. The family does their own harvesting usually with the help of neighbors. After the red and ripe cherries are picked, they are depulped by passing them through a manual depulper at the farm. The pulp itself will be used later as a natural fertilizer. The mucilage is immediately removed through the wet process which dissolves its sucrose ingredients, by leaving the beans in a processing tank anywhere from 12 to 18 hours.

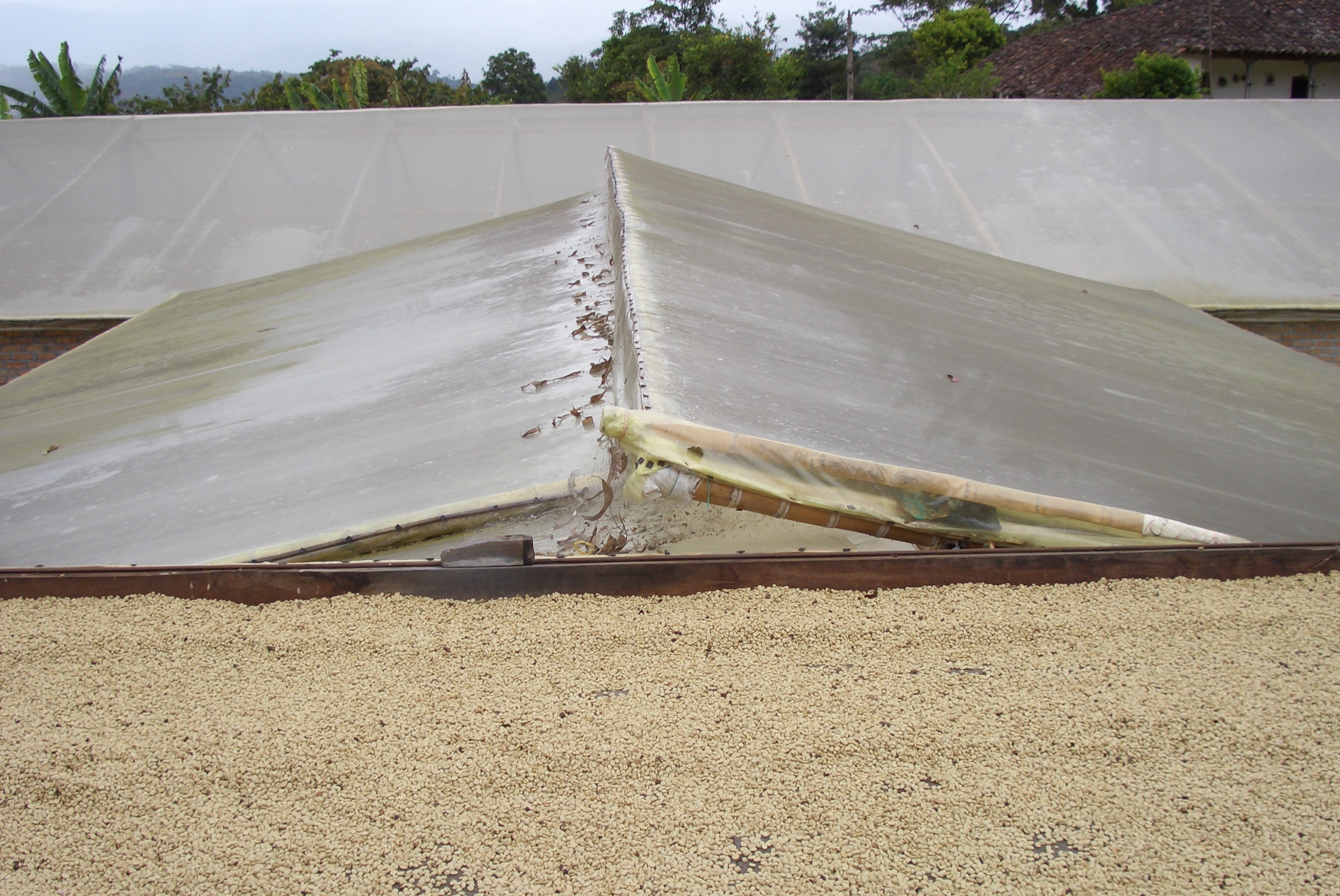

Once this process is complete, farmers sun dry the parchment on patios, or on the roofs of their houses (Elbas) They have designed a mechanism by which they can slide the roof with pulleys to cover the coffee in case of rain. The other sun drying method which is now commonly used is "marquesinas" which are raised ventilated beds covered by polyethilene.The coffee is dried and rotated to achieve the color and moisture uniformity.

The parchment is delivered directly by the producer to our own warehouse in Pitalito. At this stage, we have already agreed a premium over prevailing market prices. Once the coffee is received , it is carefully graded and cupped. The additional premiums are paid based on the cup score, evaluated by Condor's staff who are Q Graders. The yields and amount of defects are also an important factor in determining the final premium.

Producers of San Agustin, are a well selected group of small producers who understand our strict quality standards and are fully committed to produce and deliver their best coffees. We have been working with this group of farmers for the last 20 years. Among these producers, we can find several participants and some winners of COE competitions. A most recent example of one of our long term suppliers : Alirio Aguilera - Finca San Isidro, 2013 COE 1st place.

The beans have been carefully selected to meet the San Agustin quality standards. Only those who meet the cup profile standards are then milled, sorted and classified for export under the supervision of our mill manager and quality control director.This unique coffee is carefully selected by electronic sorters to produce a zero defect coffee.